Compressor oils can create unique challenges when trying to measure viscosity. Dissolved gases from refrigerants, in particular, tend to bubble out when these oils are measured using traditional viscometers. This can create errors in the measurement, typically causing readings to be much lower than they should be.

One way to get around this problem is to allow the oil sample to degas before making the viscosity measurement. One major drawback is that it can take several hours or up to a day for the oil to degas sufficiently. Fortunately there’s a better way.

The Spectro Scientific Q3000 viscometer has a unique split cell design that allows oil to flow through the measurement cell uninterrupted by outgassing. The gas in the sample is dissipated out the sides of the cell, rather than bubbling up through the sample as it is being measured. In this brief video, Dan Walsh, Director of Applications and Technical Services, explains how this works.

Highlights

The MiniVisc 3000 series (formerly the SpectroVisc Q3000 Series) viscometers are the first truly portable, solvent-free, temperature-controlled kinematic viscometers, providing high-accuracy measurements for easy detection of viscosity variations caused by contamination, mix-up and oil degradation. The devices were designed to determine kinematic viscosity at 40C in the field for applications where immediate results are essential for determining the health of critical equipment.

Principle of Operation

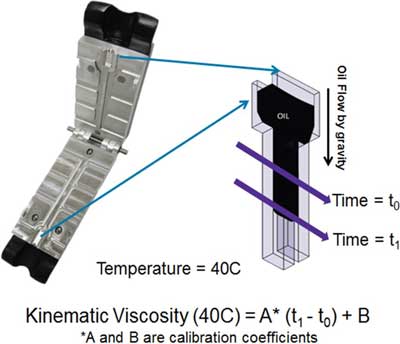

MiniVisc 3000 viscometers use a patented split cell design that enables measurement of kinematic viscosity using only a few drops (60µL) of oil. When closed, the center pieces of the split cell form a funnel with 100 micron gap allowing oil to flow down by gravity. Sensors along the funnel are triggered when oil flows by and flow time between two sensors is measured. The kinematic viscosity is then calculated. When opened, the split cell can be easily cleaned with a non-abrasive cleaning pad and ready for next sample. The split cell is controlled at 40C throughout the measurement.

The test time is proportional to viscosity, ranging from a few seconds to several minutes. The cleanliness of oil or color has no impact of the viscosity result.

Features & Benefits

| Features | Benefits |

| Direct kinematic viscosity measurement | A measure of a liquid’s flow under the influence of gravity is provided at a constant temperature, so viscosity can be compared and trended with prior readings. Requires no density check, temperature measurement, instrument pre-configuration or calculation. |

| Split-cell capillary channel | Using a very small sample size; the sampling chamber controls temperature while infrared sensors measure flow and trajectory, delivering immediate results. |

| Self-contained with high-resolution touch screen, battery and microprocessor | Enables easy operation, in sunlight or low light, drawing minimal power for a 6-hour battery life. Requires no PC. |

| Small sample size | Small sample size of 60µl (about 4 drops) is easy to obtain without impacting lubricant level. Reduces waste. |

| Temperature controlled: 40°C ± 0.1°C | Each sample is held to a constant temperature for consistently accurate readings without additional pre-test measurements |

| Works with transparent and opaque oils | Provides accurate results for even the dirtiest samples. |

| No cleaning solvent necessary | Eliminates worry about solvent disposal in remote locations. Fewer items to carry. |

| Weighs less than 1.8 kg (4 lbs.) | Designed for remote locations, the SpectroVisc Q3000 series includes a hinged cover that protects the sample chamber and touch screen while being carried by hand, in a toolbox or in a knapsack. |

| Battery operated | Stays charged for more than 6 hours. Built-in universal charger for use worldwide; region-specific power cable included. |

Product Models

| MiniVisc 3000 | MiniVisc 3050 | |

| Measurement Range | 10cSt – 350cSt | 1cSt – 700cSt |

| Extraction of 100C viscosity using Viscosity Index (VI) input | No | Yes |

| ASTM Method | ASTM Method D8092 | ASTM Method D8092 |

Combination Kits

The MiniVisc units compliment nicely with other portable oil analysis tools. They are all battery operated and require no solvent to clean.

Viscometer/FerroCheck Combination Kit

A quick check with viscosity and ferrous particle concentration in the field is the simplest way to make sure oil is good and machine wear is within alarm limits. With FerroCheck 2000, users can quickly check ferrous particle concentration up to 1%. It is a complimentary device to the MiniVisc 3000 and together they provide basic oil analysis needs for field service professionals.

Fluidscan/Viscometer Combination Kit

Fluidscan and Viscometer combination provides comprehensive oil condition to field service and lubricant service professionals. Fluidscan handheld InfraRed Oil Analyzer utilizes InfraRed spectroscopy to test oil chemistry, including Oxidation, Nitrition, Sulfation, Total Acid Number, Total Base Number, Water. The combination are deployed widely in marine vessels, power generation plants, and mining sites.